What is Yaw Misalignment?

One of the obstacles to maximizing operating margins for wind projects is the impact that yaw misalignment has on optimal turbine performance. So...

We've spent quite a bit of time discussing yaw misalignment. Our past blogs have addressed what yaw misalignment is, the different types, how it can impact your wind farm, and how you can detect it. Today, we'll be focusing on what solutions wind plant owners have to correct yaw misalignment. Watch the video below to learn more about the two types of solutions available to you.

Before you can begin to correct for static yaw misalignment, you'll need a reliable way to detect it. There are many different ways to identify and quantify misalignment, but we recommend data-based approaches that make use of the SCADA data you may already be collecting. Once you've estimated your static yaw misalignment, you can move on to correcting for it.

There are a few different methods for correcting static yaw misalignment: you may choose to adjust turbine parameters or physically adjust your wind turbine's nacelle anemometer or wind vane. As you consider your options, be sure to take into account who is responsible for the O&M of your wind turbines so that you can work with them to implement changes accurately, safely, and without violating any agreements.

Parameter adjustment for yaw misalignment correction will vary depending on the specific types of parameters that your turbines use. The first and simplest option is to check whether your turbine uses a turbine parameter that applies a constant value to the yaw error signal. If so, you can incorporate the observed yaw misalignment into the parameter.

If your turbine parameters do not contain this single value parameter, it may use a wind speed dependent table. If this is the case, you will need to take the observed yaw misalignment for each wind speed and adjust each value in the table accordingly.

Whichever path is available to you, it's essential to make sure you're adjusting the values correctly. The new value must contain the correct sign so that it removes the yaw misalignment rather than increase it. If the wrong sign is used, it will increase the yaw misalignment making the problem worse.

If turbine parameter adjustments are not available to correct for yaw misalignment, you may need to make a physical adjustment to the anemometer or wind vane itself. This is the least efficient method of correcting for misalignment because it requires a technician to climb each turbine and make individual adjustments, which takes a lot of time and effort to implement.

If you choose to make mechanical adjustments to correct yaw misalignment, you should work closely with your O&M team. Every anemometer is unique and has its own mounting configuration; you'll need to work with the right team to make this solution viable.

Correcting static yaw misalignment may seem like a daunting task, but effectively addressing it can increase your revenue and hence operating margins, as well as extend the lifespan of your wind turbines.

Looking for a partner to help optimize your wind project? WindESCo has the experience and knowledge to make it happen. In a recent engagement with UPC Renewables, WindESCo helped them identify, quantify, and correct static yaw misalignment. The result: a 2% increase in AEP. Download our case study to learn more about this project.

One of the obstacles to maximizing operating margins for wind projects is the impact that yaw misalignment has on optimal turbine performance. So...

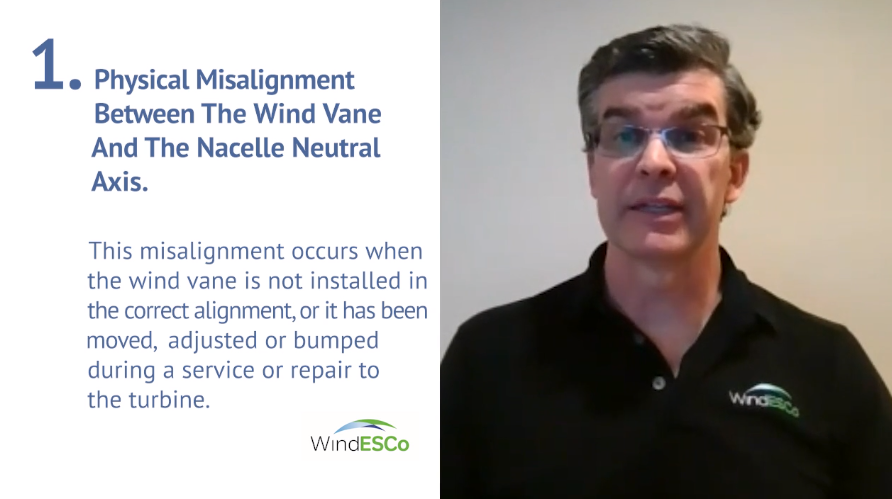

One of the most common issues that wind farm operators face is static yaw misalignment. Because this problem is invisible to the turbine controller,...

Wind farm operators are well aware that yaw misalignment can significantly reduce turbine power output. However, despite knowing and understanding...