4 Ways to Avoid POC Fatigue

Have you considered running a POC to test a turbine optimization solution at your wind plant? In our latest video, watch Sam Tasker, VP of Sales for...

When it comes to wind project operation and management (O&M), there are several strategies that project owners may follow. The distinction between these strategies comes in the form of who is responsible for wind plant operations and who assumes the risk of component failure.

This can complicate things if you are thinking about working with a third-party service provider like WindESCo to optimize your wind project. If you work directly with the OEM under a Full-Service Agreement (FSA), can you implement third-party recommendations without violating your FSA and, if applicable, your warranty?

When deciding whether to partner with a third-party provider, it is important to consider the operation and management strategy that your wind plant follows. There are three main categories that wind project O&M fall into:

Depending on your O&M strategy, you may feel more empowered to work with a third party if you so wish. We have found that owners who self-perform are the most open to our optimization solutions because they feel most free to make their own decisions—but are self-performers the only ones who can benefit from third-party solutions?

Many wind plants that work directly with OEMs are hesitant to work with third parties because they believe that the OEM will not approve third-party optimization solutions. In these types of agreements, the OEM carries the risk of component failure. If the optimization recommendations increase the risk of failure, they will have to deal with the resulting losses.

However, many wind projects and OEMs fail to consider the other side of the coin: what if optimizations increase output along with component reliability? Rather than viewing a third-party partnership as an unnecessary risk, it could be a win-win for both the OEM and the owner.

At WindESCo, we are beginning to work with more and more projects which are under FSAs. OEMs are beginning to realize that engaging with a reliable third party can lead to a win-win scenario: owners benefit from increased output and OEMs benefit from greater reliability.

How can you convince your OEM that third-party optimizations worth considering? By showing them real-world examples.

In a recent engagement, WindESCo worked with UPC Renewables to increase their wind project's AEP by 2%—all without violating its Full-Service Agreement and warranty.

Have you considered running a POC to test a turbine optimization solution at your wind plant? In our latest video, watch Sam Tasker, VP of Sales for...

Wind plant operators face many challenges: low energy prices, hefty maintenance costs, investor pressure, and tight-- if existent-- margins. And...

1 min read

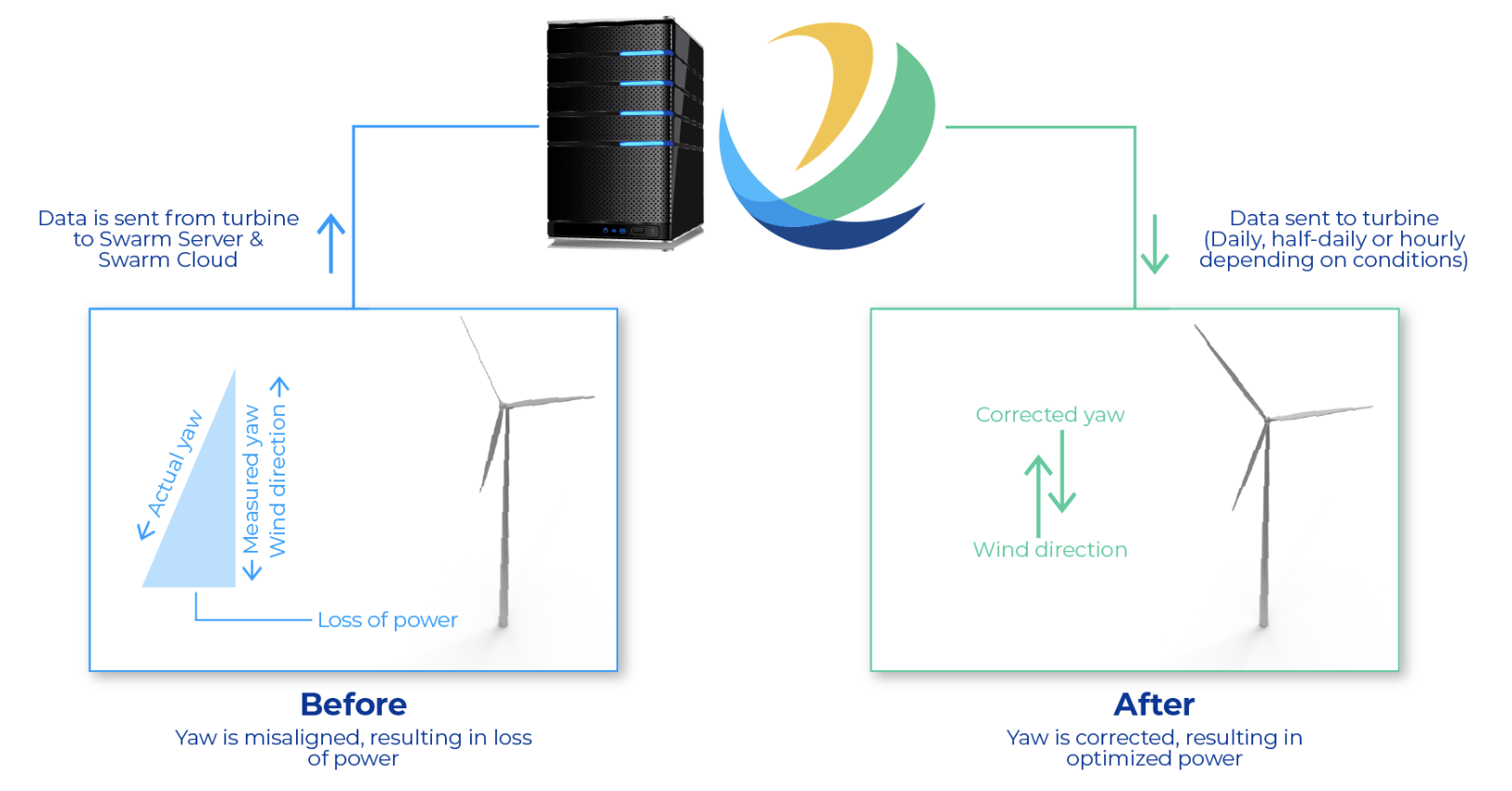

WindESCo Swarm™ is the world’s first commercially available, patented, solution for autonomous, cooperative control of wind assets. The first...