Failed anemometer

Understanding what the WindESCo failed anemometer issue check is for

What is the purpose of the turbine issue check?

- The anemometer on a given turbine appears to have failed and is providing unreliable wind speed and direction measurements.

- If the anemometer has failed, the turbine may be incorrectly cutting-in, cutting-out, or yawing non-optimally.

What does this look like?

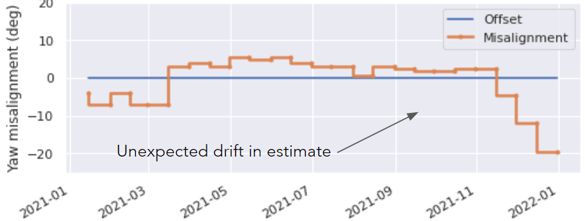

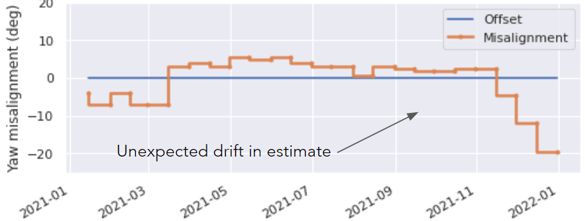

- The failed anemometer can be identified in several ways, but a clear one is through the yaw misalignment estimate that was previously consistent, but is now deviating from typical behavior

- For WindESCo, this has typically been indicative of a failure or impending failure

- A failed anemometer can also sometimes be identified by comparing rated power among peers and identifying discrepancies.

- In this case the anemometer (and therefore NTF) was biased low for 7 turbines

How can you tell the issue is corrected?

- This issue is corrected when the anemometer is replaced. In that case there would be a consistent yaw misalignment (or none) identified, and the median power would be consistent among turbines.

- For the 7 impacted turbines (second example), the anemometers were corrected and the NTF was recalibrated.

- This corrected the performance at cutout wind speeds associated to a $40,000/yr benefit for the site