Find, Fix, Measure™

Continuous, Scalable Optimization for Wind Assets

Analyzing SCADA to Improve

Actions, AEP, Reliability, Performance, Site Management, Insight, Profitability

WindESCo provides deep analytics that go beyond traditional dashboard providers. Leveraging existing SCADA, we can deliver performance and reliability improvements without the need for additional hardware. Our customers see clear and attractive returns on their investment year after year.

HOW IT WORKS

Find

Using existing SCADA, WindESCo continuously checks wind assets for opportunities to optimize performance and reliability. Finds are verified by our experts and displayed in the WindESCo portal where they can be reviewed and prioritized by your team.

Fix

WindESCo provides Fix recommendations to improve asset performance. These recommendations are used by your team, OEMs and third-party service providers to advance from availability-based KPIs to performance-based programs.

Measure

Measurement is a key feature of the WindESCo solution. Once Fixes are marked as complete, we calculate and report the performance improvement in both financial upside and additional MWh at the turbine, site and fleet levels.

0

Turbines Optimized

0M

Cubic Tons of CO2 Offset

$0

Million in Value Added

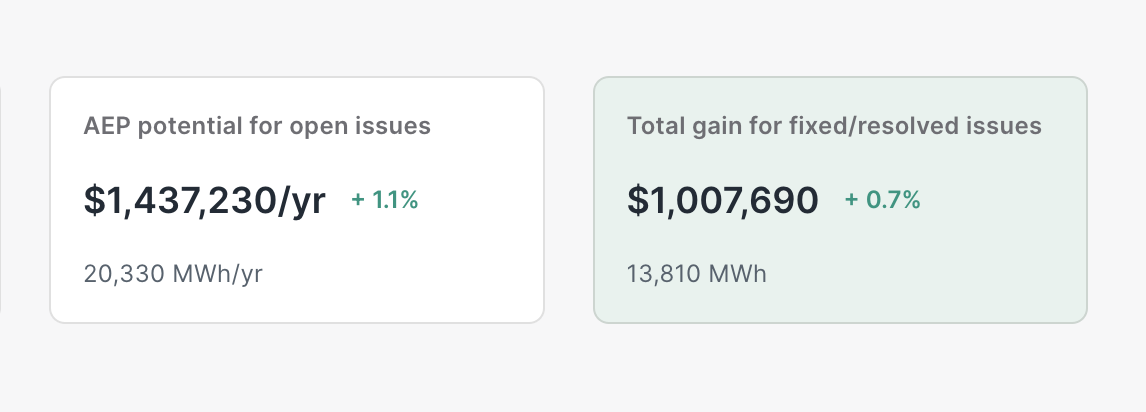

A Financial Approach to Wind Turbine Optimization

WindESCo puts the financial opportunity for wind asset optimization front and center. We provide a continuous calculation of the increased AEP and new revenue opportunities for your fleet, sites and individual assets. We help you prioritize performance and reliability improvements based on business initiatives and maintenance schedule.

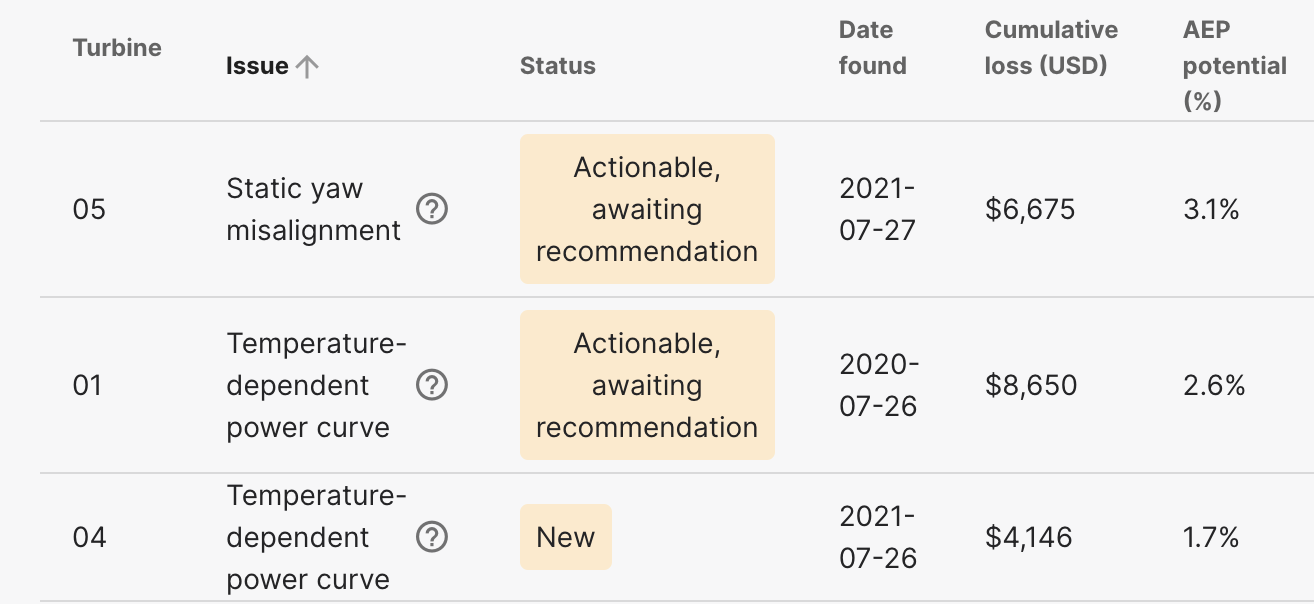

Quickly Sort and Prioritize Improvement Opportunities

Sort opportunities to improve performance to determine the most impactful actions for your site or fleet. Sort actions by AEP potential or run a campaign across your assets for a specific performance improvement.

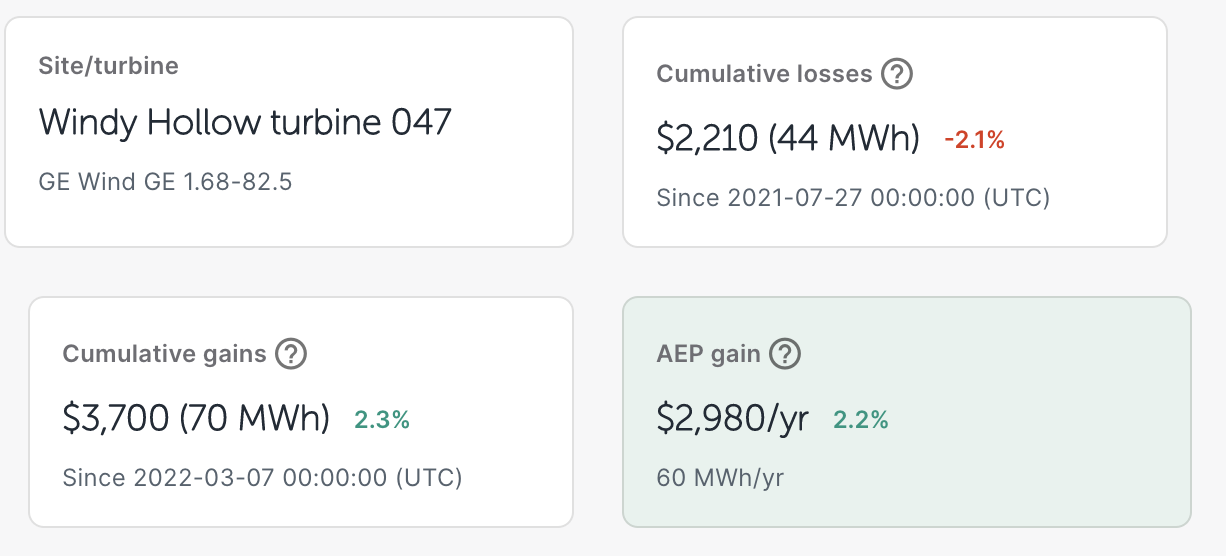

Measure the Impact of Performance Optimization

Measurement of AEP gain plays a critical role in your optimization programs. WindESCo tracks the financial and MWh impact of every improvement you make at the turbine level. See your annual and cumulative performance gains.

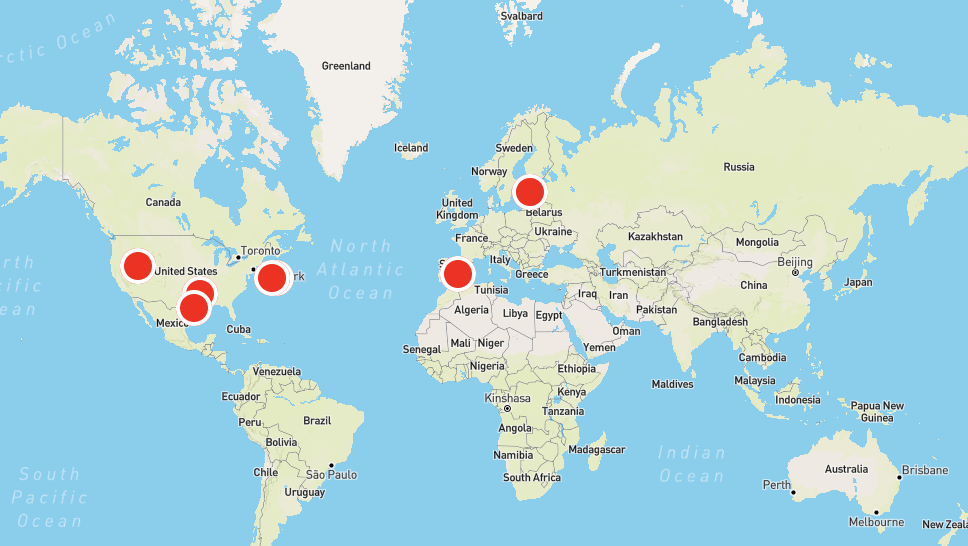

Scalable to your Entire Fleet

Performance and reliability analytics are important but doing them at scale is how operators can improve financials. Scaling Find, Fix, Measure across a fleet does not mean more work for your team. The most nimble and efficient teams in the wind industry leverage WindESCo to find optimization opportunities without adding work hours.

READ OUR CASE STUDIES

Action > Insight

With WindESCo, you'll move beyond data visualization to make actionable improvements to your turbines. Here are just a few of the optimizations real customers have implemented to improve their asset performance.

Action > Insight

With WindESCo you'll move beyond data visualization to make actionable improvements to your turbines. Here are just a few of the optimizations our customers have implemented to improve their asset performance.

Example Finds

-

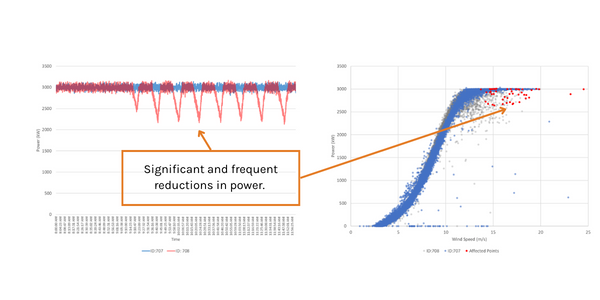

Rated Power Issue

High-frequency data detected converter fan issues that caused high temperatures. By replacing the fan the turbine increased production 2.4% and recovered $32,000 in annual revenue for the customer.

-

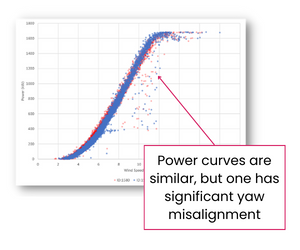

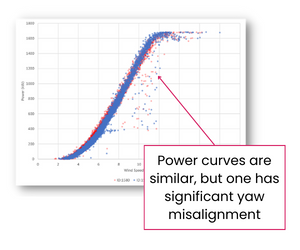

Yaw Misalignment

WindESCo found 6° of yaw misalignment on a turbine that caused 1.1% loss for the turbine and .6% loss for the plant. Through parameter changes, the customer recovered $4,300 per year for the turbine and $320,000 per year for the farm.

-

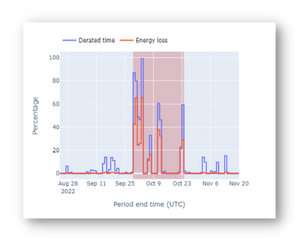

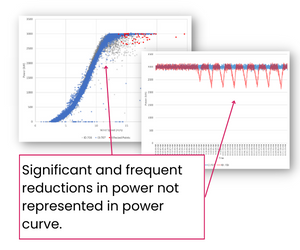

Unexpected Curtailment

Analysis of 10-minute data revealed unexpected curtailment that was not associated with a known event. WindESCo determined that an incorrect parameter had been applied to the site causing a 5% AEP impact to the farm.

-

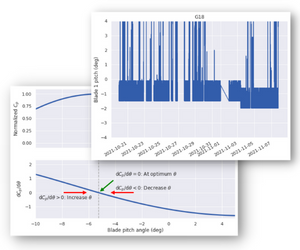

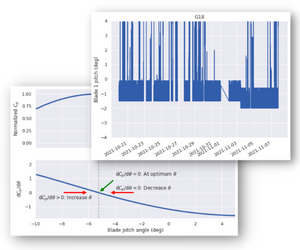

Pitch Optimization Issue

WindESCo detected non-optimal minimum pitch setting which was adjusted by 0.5°. This improved AEP for the turbine by 0.9% resulting in $131,375 increase annually.

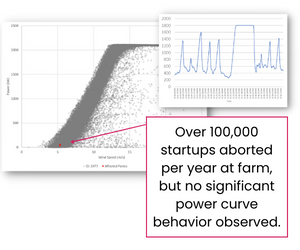

-

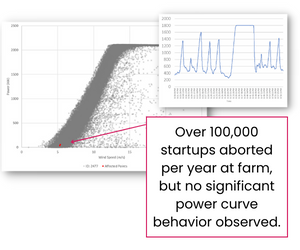

Startup Issue

High-frequency data analysis found multiple failed attempts to startup on a particular turbine. After adjusting parameters, the turbine operated as expected adding 1% AEP and $42,000/year to the plant.

-

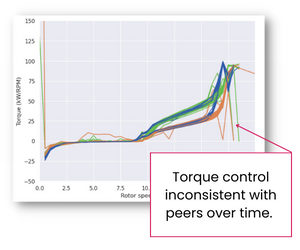

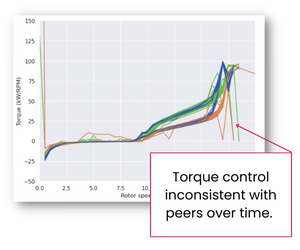

Torque Gain Inconsistency

10-minute data analysis detected the torque gain/curve was inconsistent across peers. By correcting parameter values, 0.8% AEP was gained resulting in $50,000 in additional revenue. The turbine was also protected from risk of blade damage associated with Torque issues.

Find: Rated Power Issue

|

Find |

6° Yaw Misalignment Detected |

| Fix | Change parameter for adjusting yaw misalignment |

| Measure | 1.1% AEP improvement for turbine, 0.6% for plant |

| Benefit | $4,300/Yr for turbine $320,000/yr for plant |

Find: Yaw Misalignment

|

Find |

Hight temperature due to converter fan issues |

| Fix | Repair damaged fan |

| Measure | 2.4% AEP improvement for turbine |

| Benefit | $32,000/Yr for turbine |

Find: Pitch Optimization Issue

|

Find |

Non-optimal pitch setting |

| Fix | Adjust the minimum pitch by 0.5° |

| Measure | Improved AEP by 0.9% |

| Benefit | $131,400/yr |

Find: Startup Issue

|

Find |

Multiple failed attempts at startup |

| Fix | Adjust start up turbine parameters |

| Measure | 1.0% for plant |

| Benefit | $42,000/Yr |

Find: Unexpected Curtailment

|

Find |

Unexpected curtailment not associated with known event |

| Fix | Incorrect parameter had been incorrectly applied to the site |

| Measure | 5% AEP impact to the farm while active (11 days) |

| Benefit | $15,000 cumulative losses |

Find: Torque Control Gain

|

Find |

Torque gain/curve inconsistent across peers |

| Fix | Correct parameter values for pitch-power table on 25% of turbines |

| Measure | 0.8%% AEP impact and reduced risk of blade damage |

| Benefit | $50,000/Yr |

Managing a renewable portfolio of more than 1GW without the depth of staff of a utility means our time is precious. Working with WindESCo has allowed us to prioritize optimization that make a real difference to our margins without taking focus away from other important parts of the business.

Optimize Your Wind Turbines

See for yourself why so many of the largest IPPs in the world trust WindESCo to optimize the performance and reliability of their wind assets.

Talk to Us